Out at sea, nothing stays still for long. Engines vibrate, hulls flex, and exhaust systems quietly absorb punishment every single hour. This is where marine exhaust bellows earn their keep. Often overlooked, these components face design challenges that are very different from anything on land—and getting them wrong can mean costly downtime for vessels operating along India’s busy coastlines.

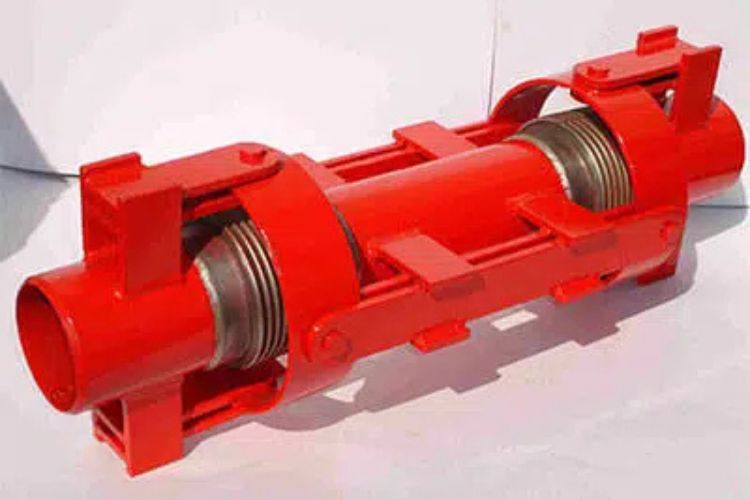

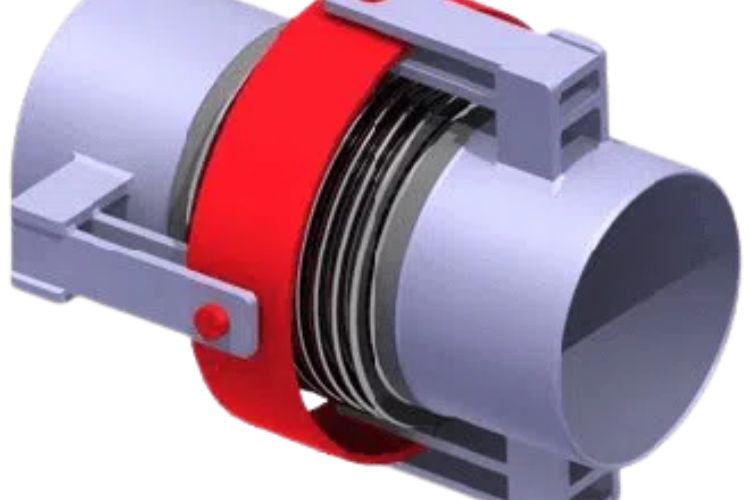

In marine engines, exhaust pipe bellows act like shock absorbers for hot gases. They compensate for movement, thermal expansion, and misalignment while keeping exhaust flow smooth. Sounds simple, but the ocean has a way of complicating even the best engineering plans.

Why Marine Exhaust Systems Are So Demanding?

Marine environments are unforgiving. Salt-laden air, constant vibration, and unpredictable load conditions create a perfect storm for mechanical fatigue. According to the U.S. National Oceanic and Atmospheric Administration (NOAA.gov), saltwater accelerates corrosion rates several times faster than non-marine environments—a fact that keeps marine engineers awake at night.

Exhaust bellows, sitting right between extreme heat and corrosive exposure, take the brunt of this stress. Unlike land-based systems that deal mostly with steady loads, marine exhaust systems must adapt continuously as vessels pitch, roll, and surge.

Key Design Challenges at Sea

1. Constant Movement and Misalignment

A ship is never truly “at rest.” Even docked vessels experience subtle hull movement. At sea, engine alignment shifts constantly due to wave action and load changes. Exhaust bellows must accommodate:

- Axial movement from thermal expansion

- Lateral displacement due to hull flexing

- Angular misalignment caused by vibration

Designing bellows that can flex repeatedly without cracking is a balancing act between flexibility and strength.

2. Extreme Temperature Cycles

Marine engines generate exhaust temperatures that can exceed 500°C, then cool rapidly when engines idle or shut down. These thermal cycles cause metal fatigue over time. Studies referenced by the American Society of Mechanical Engineers (ASME.org) highlight thermal cycling as a leading cause of expansion joint failure in high-temperature systems.

Bellows designs must account for repeated expansion and contraction without thinning, warping, or losing elasticity.

3. Corrosion from Salt and Sulphur

Fuel quality, especially in marine diesel engines, introduces sulphur compounds into exhaust gases. Combine that with salty sea air, and corrosion becomes inevitable. Designers often rely on special stainless steel grades or multi-ply constructions to slow this process—but material choice always involves trade-offs in cost and lifespan.

India-Specific Considerations for Marine Bellows

India’s maritime sector is growing fast, supported by initiatives like Sagarmala and increasing coastal shipping. Indian shipyards and operators face unique challenges—high humidity, long operating hours, and limited downtime for maintenance.

This is where sourcing reliable exhaust expansion joints India becomes critical. Designs must suit tropical climates while meeting international marine standards.

Additional factors Indian marine engineers often consider include:

- Ease of inspection during tight maintenance windows

- Compatibility with retrofitted engines

- Long service life despite variable fuel quality

Design Choices That Make a Real Difference

Experienced designers know there’s no “one-size-fits-all” solution. Some practical design approaches include:

- Multi-ply bellows construction to distribute stress evenly

- Reinforced convolutions for vibration-heavy applications

- External insulation layers to reduce thermal shock

In recent years, advancements in marine exhaust systems have also focused on fatigue life prediction and better testing methods. Research from institutions like MIT (MIT.edu) has shown that predictive stress modelling can significantly extend component life when applied correctly.

FAQs About Marine Exhaust Pipe Bellows

1. How often should marine exhaust bellows be inspected?

Most marine engineers recommend visual inspection during every major service interval, typically every 1,000–2,000 operating hours, depending on usage conditions.

2. Can standard industrial bellows be used on marine engines?

Not ideally. Marine environments demand corrosion-resistant materials and designs that handle constant movement, which standard industrial bellows may not support.

3. What materials are best for marine exhaust bellows?

High-grade stainless steels and nickel alloys are commonly used due to their resistance to heat, corrosion, and fatigue in marine conditions.

4. Do exhaust bellows affect engine efficiency?

Indirectly, yes. Properly designed bellows reduce back pressure and vibration, helping engines operate more smoothly and efficiently.

Final Thoughts

Designing exhaust pipe bellows for marine engines isn’t about ticking boxes—it’s about understanding how the sea behaves. In India’s fast-evolving maritime sector, choosing the right design can mean the difference between smooth sailing and unexpected breakdowns. When bellows are built with real-world sea conditions in mind, they quietly do their job—no drama, just reliability.

Full Audio: Listen Here