In a perfect world, every exhaust system would behave predictably. Temperatures would stay within range, vibrations would be minimal, and standard components would fit like a glove. Reality, of course, is messier. In many industrial and heavy-duty applications, off-the-shelf solutions simply don’t keep up. That’s where custom-designed components step in and nowhere is this more evident than with exhaust pipe bellows.

Why Standard Exhaust Bellows Often Fall Short?

Standard exhaust bellows are engineered for average conditions. They work well when system movements, temperatures, and pressures fall within predictable limits. But many real-world setups think power generation units, marine engines, or heavy construction machinery operate far outside those averages.

When exhaust systems experience extreme thermal expansion, misalignment, or constant vibration, generic bellows can fatigue quickly. The result? Cracks, leaks, and unexpected downtime. According to reworded insights from industrial reliability studies published by organizations like energy.gov, unplanned equipment failures often trace back to components that weren’t designed for actual operating conditions.

What Makes Custom Exhaust Pipe Bellows Different?

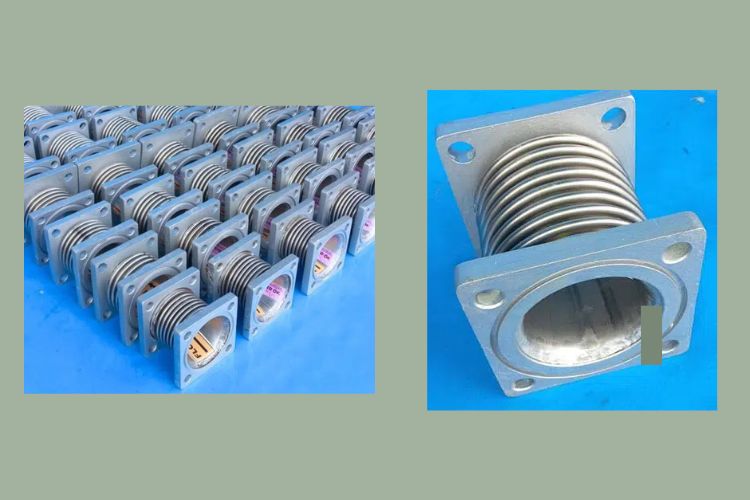

Custom exhaust pipe bellows aren’t just “made to order.” They’re engineered around your system’s specific challenges. Instead of forcing your application to adapt to a component, the component adapts to the application.

Key Variables Custom Designs Address

- Thermal movement: Precise calculations ensure the bellow absorbs expansion without overstressing the material.

- Vibration profiles: Wall thickness, convolution count, and geometry are tuned to reduce fatigue.

- Space constraints: Custom lengths and diameters fit tight or unconventional layouts.

This tailored approach often extends service life significantly sometimes by years while improving overall system stability.

Applications Where Custom Bellows Are Essential

Not every system needs customization, but certain environments almost always do. In high-load diesel engines, for example, exhaust paths experience constant thermal cycling and movement.

That’s why many engineers rely on Diesel exhaust expansion joints that are purpose-built rather than generic. These systems demand flexibility without compromising structural integrity.

Common Use Cases

- Power plants with fluctuating load cycles

- Marine engines exposed to constant vibration

- Heavy-duty generators in remote locations

- Industrial exhaust systems with complex routing

In these scenarios, customization isn’t a luxury it’s a safeguard.

Design Considerations That Truly Matter

Designing custom exhaust bellows is part engineering science, part practical experience. Material selection alone can make or break performance. Stainless steel grades, for instance, behave very differently under sustained heat and corrosive exhaust gases.

Engineers also factor in movement types axial, lateral, angular, or a combination. If you’re dealing with multi-directional movement, resources like How to Manage Complex Movements in Heavy-duty Applications? provide valuable insight into why one-size-fits-all designs struggle.

The Long-Term Value of Going Custom

At first glance, custom solutions can seem more expensive than standard parts. But seasoned operators know better. When you factor in reduced maintenance, fewer shutdowns, and longer service intervals, the total cost of ownership often drops.

- Less frequent replacement cycles

- Improved system efficiency

- Lower risk of secondary damage

Over time, custom exhaust pipe bellows tend to pay for themselves—quietly, reliably, and without drama.

FAQ: Custom Exhaust Pipe Bellows

1. When should I choose custom exhaust bellows?

If your system experiences extreme temperatures, unusual movements, or repeated failures with standard components, customization is usually the smarter option.

2. Are custom bellows harder to maintain?

Not at all. In fact, because they’re designed for your specific conditions, they often require less frequent maintenance.

3. Do custom exhaust bellows take longer to manufacture?

They do require additional design time, but the long-term reliability benefits usually outweigh the initial lead time.

4. Can custom bellows improve safety?

Yes. Properly designed bellows reduce the risk of exhaust leaks, thermal damage, and unexpected system failures.

Final Thoughts

When standard solutions start feeling like a compromise, it’s usually a sign your system deserves better. Custom exhaust pipe bellows offer a practical, proven way to handle complex movements, extreme heat, and real-world operating stress without cutting corners where it matters most.